SUCCESS STORY

Digital Transformation: vNode® optimizes traceability in a prestigious Cosmetics Production plant

Discover how data management was optimized at a leading cosmetics factory, improving real-time data integration, system interoperability and operational efficiency in industrial automation.

This Visual Basic system, a “black box” with no control or flexibility, limited operational efficiency and collaboration between IT and OT departments. The need for a modern, scalable and secure solution was urgent.

What were the challenges?

Would integrate IT and OT systems seamlessly

Offer scalability for future expansions.

Would guarantee the security and reliability of the data.

Results

Traceability optimization

Accurate tracking of boxes and pallets in real time.

IT-OT integration

Fluid communication between departments, eliminating technological barriers.

Scalability and flexibility

Adaptation to future needs without limitations.

Security and reliability

vNode® functionalities, such as Store & Forward and Reverse Connection, ensure data protection.

Implementation phases: step-by-step project execution

Infrastructure Assessment & System Design

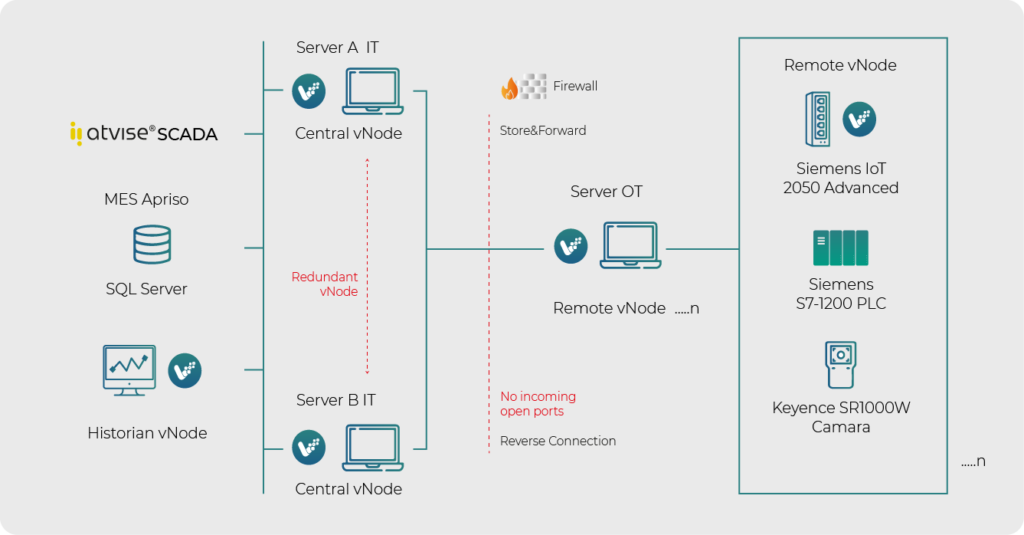

Evaluating the existing Visual Basic-based system and designing a four-tier vNode architecture for structured data flow.

Edge Device Deployment & Connectivity

Installing vNode on Siemens IoT 2050 Advanced devices and integrating with Siemens S7-1200 PLCs, Modbus devices, BACnet and Sigfox sensors.

Industrial Protocol & IT/OT Integration

Configuring OPC UA, MQTT, REST API, and SQL connections to enable seamless data exchange between SCADA, MES and cloud environments.

Security & Data Reliability Implementation

Enabling Store & Forward for data integrity, Reverse Connection to eliminate open ports and firewall configurations for secure communication.

System Validation & Commissioning

Conducting performance testing, training engineering teams, and deploying the solution with real-time monitoring via atvise® SCADA.

Key achievements

Enhanced operational efficiency

Real-time optimization reduced drilling times and improved decision-making processes.

Agility and stability

The project development time was significantly reduced, accelerating time-to-market.

Replicability and scalability

The solution was successfully replicated across various projects, establishing a strong framework for future scalability.

Advanced pressure management

Precise and dynamic pressure management led to improved safety and operational stability.

Ongoing support

Continuous technical support from vNode ensured the system’s reliability and adaptability.

“vNode® has revolutionized our industrial data management, ensuring secure and reliable transfer between networks through advanced Reverse Connection and Store & Forward features. Now, our common industrial data platform, vNode®, gives us organized, structured insights that come from any source. Its versatility allows us to easily adapt our data structure to the constant improvements we implement in our production process. With vNode®, we have found the indispensable tool to boost efficiency in our production plant.”